Carpet Construction

You know what makes a home. Here’s what makes a carpet.

Friends, family, good times and good memories make a home. So does making cookies in the kitchen, snoozing on the sofa on a rainy day, and a cozy fire come winter. These and a million other emotions, experiences and events make a home your home.

But while home consists of what’s under your roof, don’t forget what’s under your feet. Floor coverings have a huge influence on your home and home life.

Because they impact interior beauty, décor, comfort, livability and upkeep, floor coverings can make, or break, a home.

And knowing how they’re made can be very advantageous.

Knowing the different materials that make up various carpets also helps you understand and evaluate their performance aspects: why certain carpets are easier to install, why some wear better, longer, and why others are easier to care for and clean.

Plus, perhaps most importantly, understanding carpet manufacturing and materials can make you an educated customer. This will help you better determine carpet value and the beauty of the long-term investment you are about to make.

Think of fiber as the DNA of carpeting.

Fiber is the basic material that a carpet is made up of. Over ninety percent of all of the carpet made today is made up of synthetic fiber. The rest is natural fiber, most commonly wool. First, let’s look at the most common synthetic fibers.

Synthetic fibers are usually made up of one of three materials: nylon, polypropylene or polyester. All three are created by similar chemical processes using oil and natural gas.

Nylon is the sheer leader.

Almost 75% of carpet today is made of nylon and, compared to the other fibers below, it performs the best overall. Nylon is the leader in: appearance retention, fade and heat resistance, soil and stain resistance, and color and styling. The highest performance nylon is Type 6.6, which has a tighter molecular construction, making the carpet more resistant to stain penetration.

Polypropylene.

The next most common material used in carpet manufacturing is polypropylene. Introduced in the late 1950’s in Italy, polypropylene BCF has seen fast growth over the last twenty years, and today represents more than thirty-five percent of the total fibers used in the carpet industry.

Polypropylene fiber is predominantly found in loop pile carpets and is most commonly used in commercial installations (offices and other high trafficked areas).

While polypropylene is not as resilient or resistant to abrasion as nylon, it is naturally stain and fade resistant. Its natural resistance to moisture means that it must be dyed before being extruded, resulting in a more limited range of color options.

Polyester: old reliable has new applications.

The third type of material commonly used in carpet manufacturing is polyester. Polyester was introduced to the carpet industry in the mid 1960’s, and has been well accepted for its bulkiness, color clarity, and good stain and fade resistance. While not as resilient as nylon, Polyester fiber carpet constructed with today’s new technologies can be a good performer.

The pride of ownership of Wool.

The above three materials make up the majority of synthetic fibers. The other type of fiber used in carpet construction is wool fiber. While synthetic fibers are used in the manufacturing of carpets today, the original fiber used in the making of carpet was wool.

The wool used in today’s carpet comes primarily from New Zealand, Argentina, and the United Kingdom. Since wool is a natural fiber, it ranges in color from off-white to black, with many earthen tones between.

Berber, now considered a type of carpet construction, actually comes from the name of a group of North African sheepherders called the Berbers. The Berbers were known to produce very coarse wool, with characteristic color flecks in their yarns.

Although wool doesn’t stand up to abrasion and moisture as well as synthetics, it cleans well and is known to age gracefully.

Also, as a natural fiber, wool is the most ecological fiber used today. The choice of floor covering of Kings and Queens for centuries, wool carpet is the investment of a lifetime.

Industrial with a magical result, carpet making is a 3-step process.

There are basically three steps to manufacturing carpet. The first step is tufting. Tufting begins with the process of weaving the synthetic or wool fiber into a primary backing material.

The primary backing material is usually made of woven polypropylene, and its main value is to provide a base cloth to hold the yarn in place while the tufting takes place.

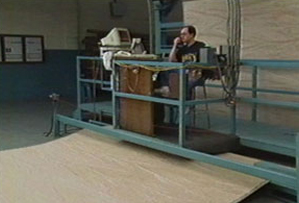

The tufting machine looks like a large-scale version of a sewing machine. It has anywhere from 800 to 2000 needles working in concert to push and pull the yarn through the primary backing material.

The typical tufting machine sits about 12 feet wide, and as its needles penetrate the backing, a small hook called a looper grabs the yarn and holds it in place. This process results in what is called loop pile construction.

An alternative step may occur at this point.

In some carpet styles the looper then rocks back against a knife, where the small loops of yarn are cut, creating what we call a cut pile carpet. The length of these cut pieces of yarn is referred to as the pile height, and is basically the distance between the looper and the primary backing.

These precision cuts are controlled by a computer, and are sometimes programmed to cut only some of the loops. This method of selectively cutting, called cut and loop construction, creates a recognizable pattern on the surface of the carpet.

Now let’s pause in our construction story to identify and explain some terms and construction variables that you may want to know about while making your carpet purchase decision.

Pile height, or nap, is the length of the tuft measured from the primary backing to the yarn tips. Shorter pile heights tend to show less matting and crushing than longer pile heights.

The stitch rate of a carpet is measured in penetrations, or tufts, in a given length of carpet, usually an inch. The stitch rate is controlled by how fast the carpet is moved through the tufting machine. Stitch rate is a partial indicator of the finished products density. The greater the stitch rate the denser the carpet.

The gauge of the tufting machine is measured by the number of needles measured across a given length, also generally in inches. The smaller the gauge means more needles and ultimately a denser carpet construction.

Twist is equally if not more important than the other components. The number of times the yarn ends are twisted together generally represents the performance of the carpet. The more twists in the yarn ends equals greater performance. It is ultimately the “untwisting” of the yarns that leads to poor performance. So when looking at twist, more and tighter is better.

Face weight is determined by the actual amount of fiber per square yard, and is measured in ounces. Face weight is only one of the many criteria that determine the lasting beauty of carpet.

Dye application is step two in the creation of carpet.

Now the carpet is taken through one of two dyeing processes. The first method of dyeing is called yarn dyeing, or sometimes pre-dyeing, where the color is applied to the yarn prior to tufting.

The advantages of all yarn dyeing methods include good side-by-side color consistency, large lot sizes, and uniformity.

The second method involves applying color to the yarn after the carpet has been tufted. This is the method by which most residential carpeting is dyed. There are several carpet dyeing methods in use, each producing a unique end result.

The first technique, often referred to as Beck, or batch dyeing, involves stitching the ends of the carpet together, and then running the tufted carpet loop through large vats of dye and water for several hours. The Beck process is ideal for smaller production runs, and heavier face weight products.

Continuous dyeing involves running the carpet through and under several dye heads that apply color directly to the carpet face via a continual spraying or printing. This process is also used to create multicolor or patterned effects in the carpet.

Screen printing is another common method of carpet coloring, where color is applied through anywhere from one to as many as eight silk-screens.

The major benefits of carpet dyeing, that is dyeing the carpet after the tufting process, are greater color flexibility and efficiency.

The third and final step is the finishing process.

This process is typically a single production line that completes the final stage of the carpet construction.

In the finishing process, a coating of latex is applied to both the tufted, dyed carpet’s primary backing, and also to secondary backing. Secondary backing is typically made of a woven synthetic polypropylene material. The two parts are squeezed together in a large heated press, where they are held firmly to preserve the backings stability.

Shearing, one of the final stages in the manufacture of carpet is the process of removing all of the little loose ends and projecting fibers that might have been created during the tufting process. It also helps achieve the yarn’s tip definition of the finished carpet.

Finally, each carpet is carefully inspected for color uniformity and other manufacturing defects before it is rolled, wrapped, and shipped.

That’s our brief explanation of how carpet is made.

We hope that the information here leads you to a better understanding of how this beautiful and versatile product is created and that how a well-made, well- chosen carpet can help make your home.